Egg-layer vs Static Brick Machine

- Dane Doubell

- Sep 21, 2016

- 2 min read

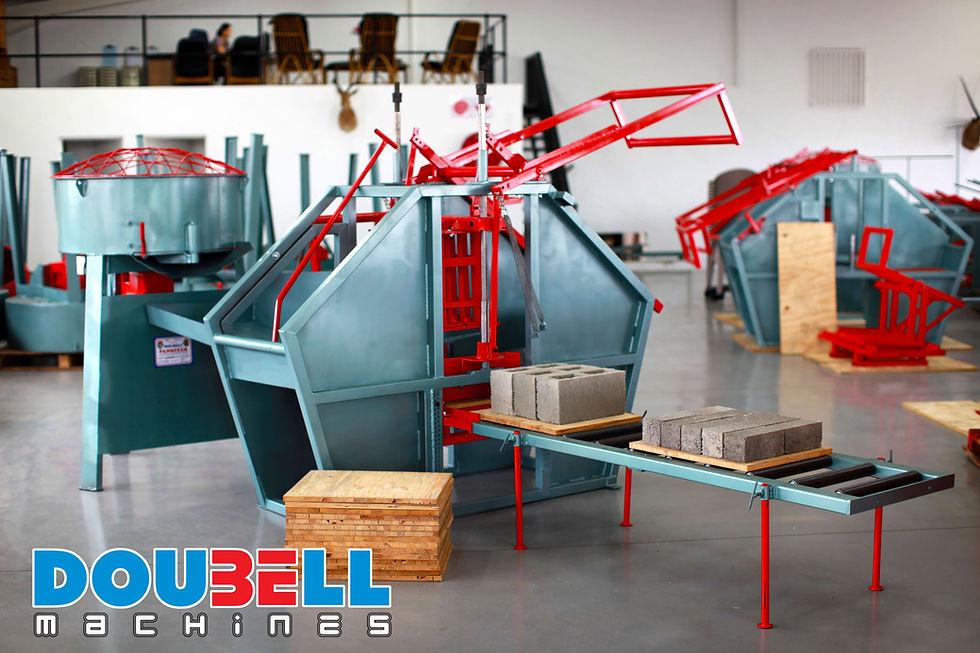

STATIC BRICK MACHINE

Brick & Block production is done on wooden boards or pallets. The machinery remains stationary & the production is extruded out along a conveyor system of some kind.

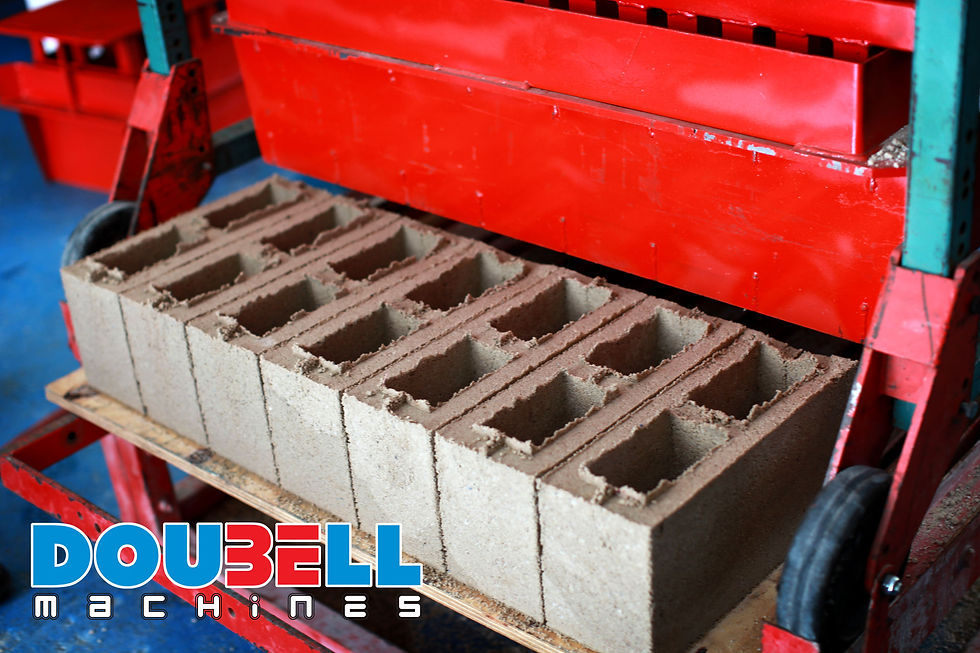

EGG-LAYER BRICK MACHINE

Production of bricks occurs on a concrete slab. The machinery is not stationary - instead it moves along on wheels. Aggregate is fed into the machine & the bricks are compacted in place, after which the machinery is moved forward (or backwards depending on perspective) off the bricks. This system has been compared to a chicken laying eggs; hence the term "egg-layer."

METHOD COMPARISON

Static machinery boards are prone to handling breakages

Egglayers require costly concrete slabs that are thick enough to prevent vibration travel to the bricks behind

Wooden boards are cheaper to outlay capital for a day's production; But they will not last as long as a concrete slab.

Static machines can have panmixers adjacent to eliminate the need to transport mixture to & from the machinery to a mixing station.

Egglayer brick machines can be moved into secure garages to lock up for safety

Static machines have a limited "per drop" quantity because too much production makes the boards too heavy for the workers to handle efficiently all day

Static machines can have TWO vibrator motors on top & below for superior vibration, which provides moreuniform compaction in the brick as well as faster cycle times

DOUBELL FACTORY PREFERENCES

Doubell Machines would advise you to consider your unique situation when determining which system of brickyard set-up is preferable; However there are some generic starting points of advice:

If you want to manufacture building units that will be plastered & appearance is not critical, rather aim for higher production machinery such as the Jumbo MK3. This will also reduce your actual unit costs by providing more bricks / blocks in a day for the same overall fixed costs.

If you want to produce high-quality pavers, consider a static set-up such as the Hyperstat. The dual vibration will certainly make an impact when dealing with finer material such as sand (river/plaster/building sand) and/or fine grit or crusher dust.

The Jumbo MK3 on a Static Adaptor with an additional vibrator motor is a perfect merge of both high quality & high production. This system works best if you only intend producing pavers, but boards can be heavy (90kg or 195lbs) but certainly manageable.

In either scenario, both brick-manufacturing systems can be run without electricity when the desperate need arises (at least for Doubell machinery).

Last tip for either situation is to use some Doubell Quickmix liquid. It will quite definitely offer a smoother appearance to your bricks / pavers as well as help the brick slide out the mould easier.

Comments